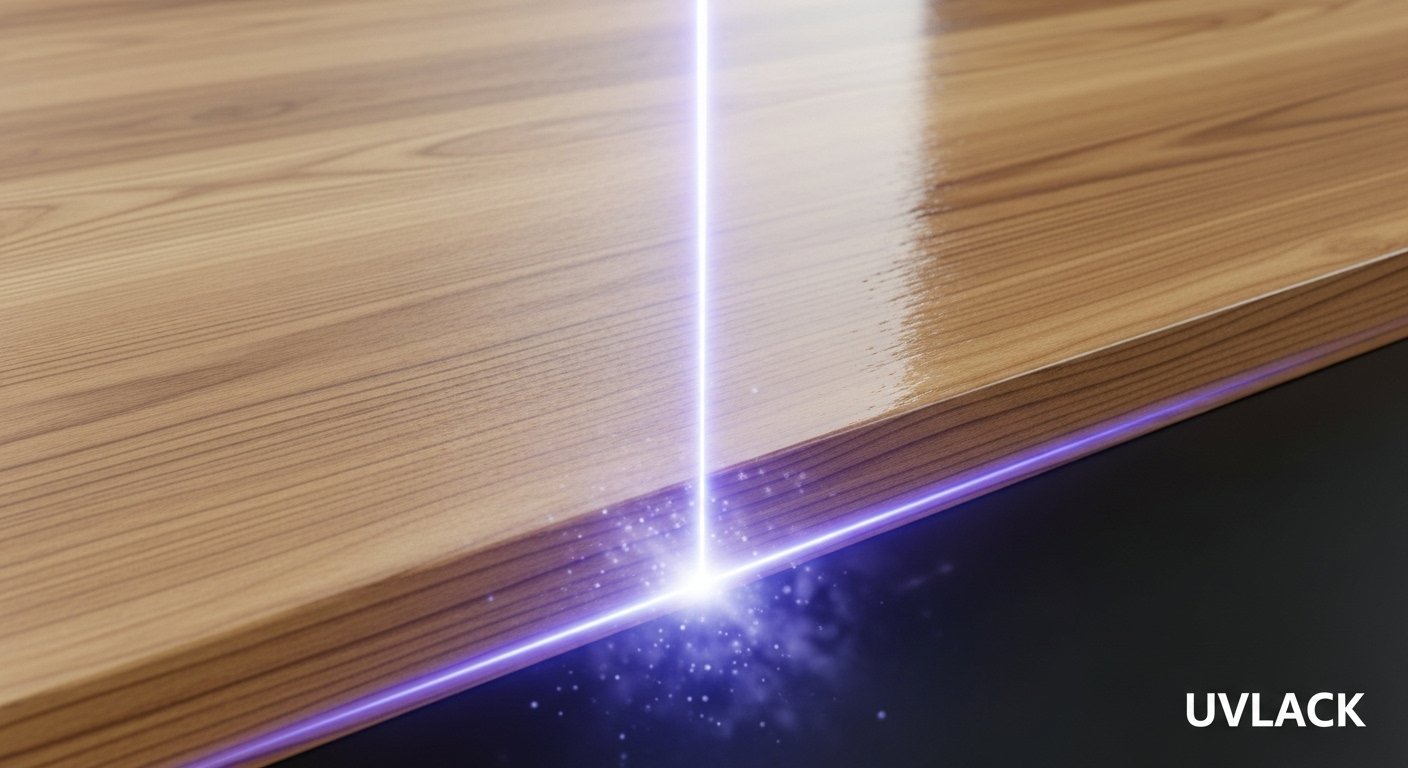

Did you know that traditional coatings can take hours or even days to dry, while UVLACK cures in mere seconds, slashing production time by up to 90 percent? This game-changing technology is reshaping how manufacturers approach surface finishing, offering speed without sacrificing quality.

Understanding UVLACK

UVLACK stands for UV-cured lacquer technology, a process that uses ultraviolet light to harden coatings almost instantly. At its core, it combines special resins with photoinitiators, those clever molecules that kick off a reaction when hit by UV rays. You might think of it as sunlight on steroids, but controlled in a factory setting.

This method started gaining traction back in the 1960s, first in printing, then spreading to wood and beyond. Today, it’s prized for being low in volatile organic compounds (VOCs), those pesky emissions that harm the air. Companies like Sherwin-Williams have rolled out lines of UV-curable lacquers that go on smooth and cure fast, perfect for busy production lines.

If you’re wondering why it matters, consider this: UVLACK creates a tough, scratch-resistant layer that protects surfaces from daily wear. It’s like giving your products an invisible shield, all while keeping things eco-friendly.

Benefits of UVLACK in Manufacturing

Switching to UVLACK brings a host of perks that can transform your operations. Let’s break it down.

Speed Boost: Traditional drying might tie up space for hours, but UVLACK hardens in seconds under UV light. This means faster turnaround and higher output, as seen in furniture giants like IKEA, who use it to keep costs down and shelves stocked.

Eco-Friendly Edge: With VOC emissions dropping by 90 to 99 percent compared to solvent-based options, UVLACK helps meet strict regulations in places like Europe and the US. It’s a win for the planet and your compliance checklist.

Durability That Lasts: The cured finish resists chemicals, scratches, and fading from sunlight. For example, in flooring, it prevents yellowing and handles foot traffic like a champ.

Cost Savings Over Time: Less energy use (think 30 to 40 percent reductions with UV LED variants) and minimal waste add up. Plus, no need for bulky drying ovens, freeing up floor space.

You might wonder if the upfront cost is worth it. From what I’ve seen, the quick ROI through efficiency makes it a smart bet for growing businesses.

How UVLACK Works: Step-by-Step Guide

Curious about the magic behind UVLACK? It’s simpler than you think. Here’s a clear breakdown.

First, prepare the surface: Clean your wood, metal, or plastic base to ensure good adhesion. Dust or oils can spoil the bond, so a quick wipe-down does the trick.

Next, apply the coating: Use rollers, sprays, or curtains to spread the UVLACK evenly. Brands like Chimiver offer water-based options that flow nicely without drips.

Then, expose to UV light: Pass the item under UV lamps or LEDs. Photoinitiators in the mix absorb the light, sparking a chain reaction that links molecules into a solid film. This polymerization happens in seconds, releasing a bit of heat but nothing extreme.

Finally, inspect and finish: The surface is ready for handling right away. No waiting around.

For a visual, imagine a conveyor belt: Item goes in wet, comes out dry and tough. The chart below outlines typical curing times.

| Step | Time Estimate | Key Tip |

|---|---|---|

| Surface Prep | 5-10 minutes | Use alcohol wipes for best results |

| Application | 1-2 minutes | Aim for 20-50 microns thickness |

| UV Exposure | 1-5 seconds | Adjust intensity for thicker layers |

| Inspection | Immediate | Check for uniform gloss |

This process beats traditional methods hands down, especially for high-volume runs.

Applications of UVLACK Across Industries

UVLACK isn’t just for one niche; it’s versatile across sectors. Here’s where it shines.

Wood and Furniture: From cabinets to tables, UVLACK delivers glossy, resistant finishes. Excelitas systems cure varnishes on MDF panels, making them ideal for kitchens where spills are common.

Automotive: Headlights and interiors get a protective layer that’s UV-stable and scratch-proof. It even bonds adhesives in assembly lines.

Electronics: Conformal coatings shield circuit boards from moisture and dust. Toagosei America’s products seal components, extending gadget life.

Packaging: Food-safe lacquers on cartons add barriers against oxygen and grease, keeping products fresh longer.

Flooring and Decor: Parquet floors cure quickly, resisting wear in busy homes. Decorative mouldings get a uniform sheen without yellowing.

Real-world example: Clean Armor uses UVLACK for tabletops, creating self-leveling, no-shrink finishes in minutes. It’s also popping up in nails and marine applications for that extra toughness.

Common Mistakes to Avoid with UVLACK

Even pros slip up sometimes. Here’s how to steer clear of pitfalls.

Over-Curing the Coating: Too much UV exposure can make the surface brittle or reduce adhesion for overlays. Stick to recommended times, usually 1 to 5 seconds, and test small batches.

Ignoring Surface Prep: Skipping cleaning leads to poor bonding. Always degrease and check substrate compatibility, especially with plastics.

Wrong Equipment Setup: Using outdated lamps causes uneven curing. Opt for LED systems for consistency, and maintain them to avoid power drops below 90 percent.

Handling Uncured Materials Carelessly: Raw UVLACK can irritate skin. Wear gloves and ventilate areas to prevent issues.

Not Accounting for Thickness: Thick layers might not cure fully inside. Apply in thin coats and adjust light distance.

You might think, “Does this really happen often?” Yes, but simple checks like monitoring lamp output fix most problems.

Future Trends in UVLACK Technology

Looking ahead, UVLACK is evolving fast. The market could hit $12.2 billion by 2032, fueled by green demands.

LED advancements lead the way, with longer lifespans (up to 40,000 hours) and lower energy use. Hybrid systems mix LED and traditional UV for flexibility.

Bio-based options are rising, using renewable resins to cut environmental impact further. Waterborne UVLACK, like those modified with zinc oxide for superhydrophobicity, adds self-cleaning perks.

Smart integration with Industry 4.0 means automated lines with real-time monitoring. Excimer tech creates ultra-matte, fingerprint-resistant surfaces for premium goods.

In automotive and electronics, expect more antimicrobial coatings. As regulations tighten on VOCs, UVLACK will become the go-to for sustainable manufacturing.

To wrap up, UVLACK offers a blend of speed, strength, and sustainability that’s hard to beat. If you’re in manufacturing, start small: Test it on a prototype line. Or reach out to suppliers like GEW for a demo. What’s one tweak you’ll make to explore UVLACK today?

You May Also Like: Cbybxrf Explained: The Future of Innovation and Adaptability

FAQs

What exactly is UVLACK?

UVLACK is shorthand for UV-cured lacquer technology, a method that hardens coatings using UV light for quick, durable results.

Is UVLACK safe for the environment?

Yes, it emits far fewer VOCs than traditional coatings, often reducing them by over 90 percent, making it a greener choice.

Can UVLACK be used on any surface?

It’s versatile for wood, metal, plastic, and more, but always test adhesion on your specific material.

How does UVLACK compare to traditional lacquers?

It cures faster, uses less energy, and provides better resistance, though it needs UV equipment upfront.

What industries benefit most from UVLACK?

Furniture, automotive, electronics, and packaging see big gains in speed and quality.

Are there any health risks with UVLACK?

Uncured materials can irritate skin, so use protective gear; once cured, it’s safe.

What’s the cost like for starting with UVLACK?

Initial setup varies, but savings from efficiency often pay off within a year for medium-scale operations.