Key Takeaways

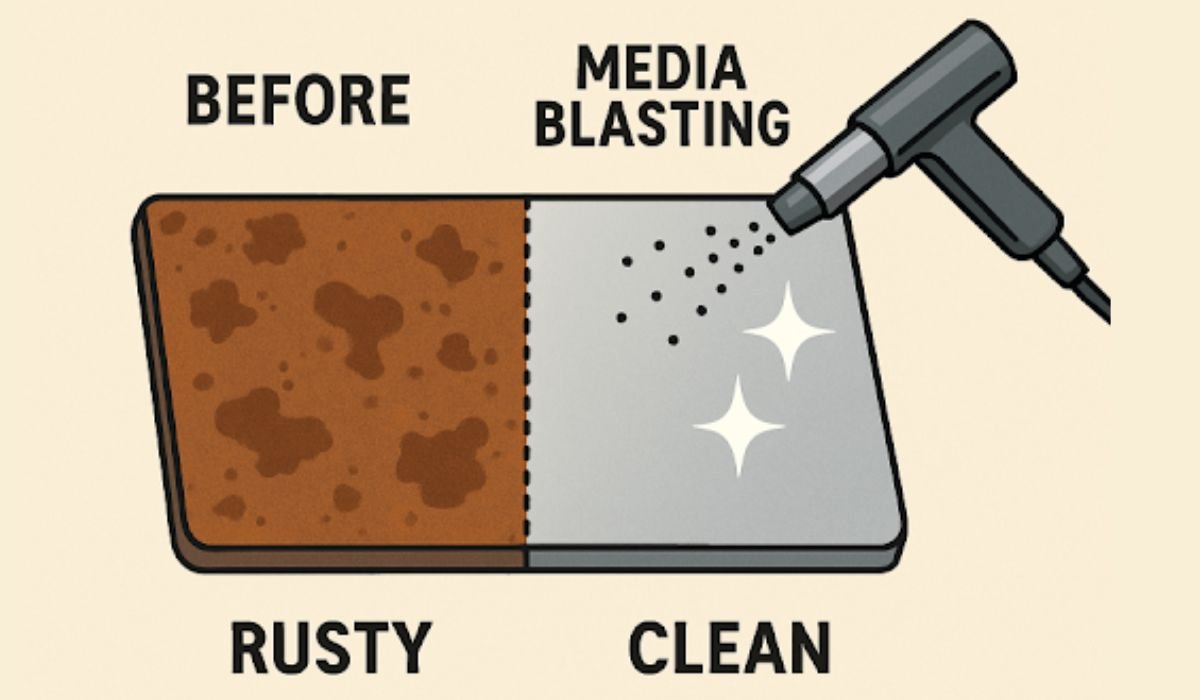

- Media blasting effectively removes contaminants, rust, and old coatings, providing a clean surface for new applications.

- Various industries, including automotive, aerospace, and construction, rely on media blasting for efficient surface preparation.

- Choosing the appropriate blasting media is crucial for achieving desired results without damaging the substrate.

Introduction to Media Blasting

Media blasting is a transformative surface preparation technique essential to industries where cleanliness and adhesion are crucial. Also known as abrasive blasting, this process uses propelled abrasive materials at high velocities to clean surfaces, delivering pristine results every time. By removing contaminants, rust, paint, or other layers, professionals ensure surfaces are ready for painting, coating, or bonding. For those requiring tailored solutions, exploring Blast Media options is essential to achieving the desired outcome for various surfaces. The flexibility of media blasting lies in its ability to handle surfaces ranging from robust steel structures to delicate composites. It’s recognized in many sectors as the gold standard for restoring, renovating, or upgrading substrates, extending their usable life and performance. Whether revitalizing industrial equipment or preparing architectural landmarks for restoration, the proper blasting process yields both cosmetic and functional benefits.

Benefits of Media Blasting

The rise of media blasting across industries stems from its outstanding benefits. One of its main strengths is efficient cleaning, as it dramatically reduces preparation time by stripping away layers quickly and thoroughly. This swift turnaround is a significant advantage, particularly for facilities that face tight schedules and high demands. Another key benefit is enhanced adhesion. By roughening surfaces at a microscopic level, media blasting significantly improves the bonding between surface and coatings or adhesives, making finished products last longer and resist environmental wear.

Additionally, media blasting is remarkably versatile, usable on a vast range of materials—metals, plastics, composites—without causing unwanted warping or damage. This versatility enables businesses to utilize it for both maintenance and manufacturing activities. Beyond these advantages, studies suggest that well-prepared surfaces are crucial for the longevity of structures, aligning with expert guidance in the field of coatings technology. You can find further insights on best practices at PPG Industrial Powder Coatings, a recognized industry resource on surface preparation and coatings.

Applications Across Industries

Media blasting is an essential process across different sectors, designed to meet the specific demands and standards unique to each field:

- Automotive: Used to treat vehicle bodies, frames, and parts, media blasting ensures thorough removal of rust, old paint, and grime. This lays the groundwork for even coating applications, improving appearance, and boosting long-term durability.

- Aerospace: Aircraft and spacecraft rely on spotless surfaces for both safety and performance. Media blasting is frequently used to clean, strip, or texture components, helping meet strict regulatory standards imposed by aviation authorities.

- Construction: In building maintenance and restoration, media blasting removes weathered finishes, corrosion, or graffiti from surfaces. The process enables reliable repainting, sealing, or other protective measures to maintain the integrity of the underlying structure.

These applications underscore why media blasting has become integral in meeting industry guidelines and customer expectations.

Choosing the Right Blasting Media

Success in media blasting relies on picking the right abrasive for the job. The choice determines not just surface cleanliness but also the number of passes needed and the potential for substrate damage. Three of the most popular media types include:

- Sand: A classic choice for general cleaning, but its coarseness can be excessive for fragile surfaces like aluminum or fiberglass.

- Glass Beads: Favored for polishing and producing a uniform finish. Suitable for projects where aesthetics matter and less aggressive removal is desired.

- Steel Shot: Chosen for the heaviest-duty applications, its mass delivers deep-cleaning power, often increasing the strength of materials such as steel through a process called peening.

There are even specialized media available—such as plastic beads or walnut shells—ideal for delicate tasks or environmentally sensitive operations. The evolution of blasting media reflects the industry’s responsiveness to changing regulatory and sustainability demands.

Environmental and Safety Considerations

Professionals must strike a balance between effectiveness and safety to prevent hazards associated with airborne dust and particulates. Proper ventilation and the use of protective gear, such as respirators and goggles, are non-negotiable. Companies are also increasingly opting for low-dust and biodegradable media, making surface preparation safer for workers and less impactful on the environment. Regulatory bodies, such as OSHA, provide guidelines for safe practices, and it’s essential to stay current with these standards to safeguard workers and the surrounding environment (see OSHA’s silica safety resources). Regular safety training ensures everyone remains aware of best practices and legal requirements.

Conclusion

Media blasting stands out as a versatile and highly effective method for surface preparation, trusted across a spectrum of industries. Its ability to rapidly clean, texture, and rejuvenate surfaces while promoting stronger finishes makes it indispensable. Careful selection of blasting media, adherence to safety best practices, and a focus on environmental responsibility empower businesses to maximize benefits without compromise. By embracing these standards and innovations, organizations ensure their products, equipment, and infrastructure remain durable, safe, and fit for future challenges.