Key Takeaways

- The right dispensing equipment ensures efficiency, precision, and reduced waste.

- Automation is ideal for high-volume production, while manual tools suit smaller-scale tasks.

- New technologies like jetting systems and IoT-enabled equipment are driving accuracy and productivity.

Introduction

Choosing the right dispensing equipment can profoundly impact your adhesive application process, influencing efficiency, product quality, and operating costs. With countless adhesive options on the market, matching the right equipment to your specific adhesive and application is essential. Whether establishing a new production line or upgrading an existing system, working with a reliable packaging company can be a valuable first step in ensuring seamless integration and expertise in equipment selection.

The growing complexity and expectations in today’s manufacturing environments demand dispensing solutions that can deliver speed, adaptability, and precision. Investing in the appropriate system means improving workflow, cutting waste, and ensuring products consistently meet quality standards. As industries like automotive, electronics, and packaging expand, understanding how to choose dispensing equipment that fits your needs has never been more critical.

Understanding Adhesive Types and Their Requirements

Each adhesive possesses unique properties that must be matched with the correct dispensing system. Factors like viscosity, curing mechanism, and chemical sensitivity can affect how the adhesive should be handled and applied. For instance, certain high-viscosity adhesives can be difficult to dispense consistently without the support of pressurized or augmented systems. Likewise, adhesives that set when exposed to moisture or UV light may require specialized environments or integrated curing hardware.

Careful analysis of the adhesive’s viscosity and your production process’s physical and chemical requirements will prevent costly equipment mismatches. According to Assembly Magazine, aligning equipment with adhesive requirements is crucial for minimizing waste and preventing production hiccups caused by clogs or incomplete curing.

- Viscosity: High-viscosity products need powerful pumps and precision controls to avoid inconsistent application or clogging.

- Curing Mechanism: UV-cured and heat-cured adhesives may need equipment with integrated lamps or environmental controls for optimal performance.

Types of Dispensing Equipment

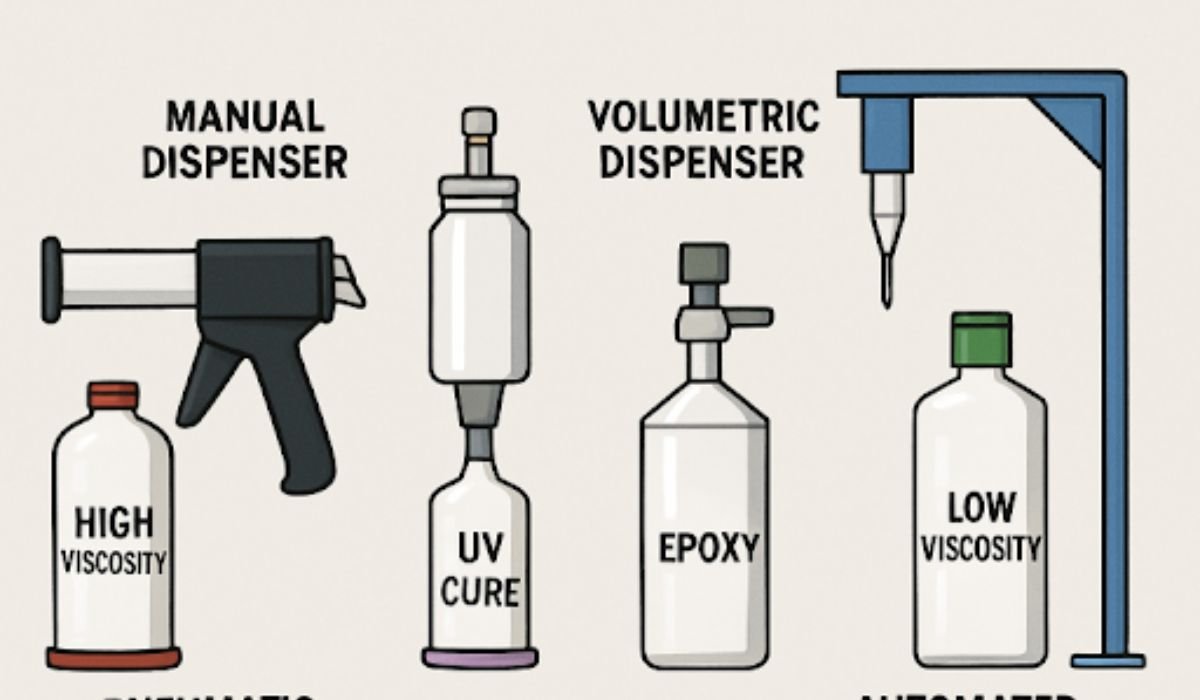

Adhesive dispensing equipment comes in several forms, each optimized for specific applications and production scales:

- Manual Dispensers: Best for low-volume applications, repairs, and prototyping. These are cost-effective but lack the speed and precision for larger-scale operations.

- Pneumatic Dispensers: These systems utilize air pressure and deliver increased control over flow rates, making them ideal for moderate production volumes and repetitive tasks.

- Volumetric Dispensers: Ensure exact quantities are dispensed every time. These are vital for tasks requiring uncompromising precision, helping to avoid overuse or underapplication.

- Automated Dispensing Systems: These systems leverage robotics and highly controlled axes for seamless, high-speed dispensing. They are suited to demanding operations in large-scale manufacturing environments where repeatability and throughput are prioritized.

Factors to Consider When Selecting Dispensing Equipment

Proper selection of dispensing equipment requires careful assessment of your production goals and constraints. Consider these key factors when making a decision:

- Production Volume: For high-volume manufacturers, automation offers a way to scale output without compromising quality or efficiency.

- Precision Requirements: Critical applications—such as those in electronics, medical devices, or aerospace—often necessitate ultra-precise, programmable dispensing solutions.

- Integration with Existing Systems: Ensure your new equipment will interface smoothly with current workflow, software, and machinery, reducing integration bottlenecks and retraining needs.

- Maintenance Needs: Seek solutions offering easy access for cleaning and servicing to minimize downtime and prolong equipment life. Preventive maintenance and fast repairability enhance productivity and protect your investment.

Additionally, consider consulting Industrial Equipment News for deeper insight into how production variables impact your choice of dispensing equipment.

Advancements in Dispensing Technology

In recent years, major innovations in adhesive dispensing have been seen, including precise jetting technology that enables microdispensing in challenging applications. Jetting systems, commonly used in electronics and medical device manufacturing, can deliver minuscule droplets with high repeatability and accuracy—ideal where manual methods fall short. Other state-of-the-art systems now feature connectivity with industrial IoT networks, providing real-time feedback on dispensing performance and predictive maintenance alerts for minimal downtime.

Another advancement is automated vision systems, which allow machines to detect and adjust dispensed adhesive lines in real time, ensuring accuracy regardless of changes in the workpiece or operating environment.

Market Trends and Growth

The global adhesive dispensing equipment market is expanding quickly, projected to reach $19.6 billion by 2033 with a 5.3% compound annual growth rate. Increased production in automotive components, advancements in electronics, and the exponential growth of the packaging sector are all fueling this momentum. Manufacturers worldwide leverage modern, automated systems to keep pace with demand while boosting consistency and traceability.

Manufacturing facilities embracing new dispensing technologies are improving productivity and gaining a competitive market edge by delivering superior-quality products faster.

Final Thoughts

Investing in the right adhesive dispensing equipment can profoundly impact your manufacturing output and quality control. By thoroughly evaluating your adhesive options, production needs, and the latest technological advances, you position your operations to meet evolving industry standards and customer expectations. For businesses aiming to grow and compete globally, the right dispensing system isn’t just an expense—it’s an essential, strategic investment.